Inventory management is changing fast. New technologies and ideas are making it easier for businesses to track and control their stock.

This blog post will explore the exciting trends and innovations shaping the future of inventory management. These tools are revolutionizing how businesses handle their stock, from advanced inventory software to integrated inventory management system software.

Let’s explore the key developments that are set to transform this crucial aspect of business operations.

What Is Inventory Management?

Inventory management is overseeing and controlling a company’s stock of goods. This includes raw materials, work-in-progress items, and finished products. Effective inventory management ensures businesses have the right products in the right quantities at the right time. It helps prevent stockouts, reduces excess inventory, and optimizes cash flow.

Modern inventory management goes beyond simply counting items. It involves forecasting demand, tracking stock levels, and streamlining the supply chain. With the rise of technology, many companies now use inventory management system software to automate and improve these processes.

Trends Shaping the Future of Inventory Management

As we look to the future, several key trends are transforming how businesses handle their inventory:

1. Artificial Intelligence and Machine Learning

AI and machine learning are revolutionizing inventory management. These technologies analyze vast amounts of data to predict demand more accurately. They can spot patterns humans might miss, leading to better stock decisions.

For example, AI can:

- Forecast seasonal trends

- Suggest optimal reorder points

- Identify slow-moving items

This results in less wasted stock and improved cash flow. As AI continues to advance, its role in inventory management will only grow.

2. Internet of Things (IoT) Integration

IoT devices are changing how we track and monitor inventory. Smart sensors can now provide real-time data on stock levels, location, and condition. This technology offers several benefits:

- Automatic stock updates

- Improved accuracy in inventory counts

- Early detection of quality issues

By connecting physical inventory to digital systems, IoT creates a more responsive and efficient supply chain.

3. Blockchain Technology

Blockchain is set to enhance transparency and traceability in inventory management. This technology creates an unalterable record of transactions. For an inventory, this means:

- Better tracking of products from source to customer

- Reduced risk of fraud or counterfeit goods

- Improved coordination between supply chain partners

As blockchain matures, it will likely be crucial in managing complex, global supply chains.

4. Robotics and Automation

Warehouses are increasingly turning to robots and automated systems. These technologies can:

- Pick and pack orders faster than humans

- Operate 24/7 without breaks

- Reduce errors in inventory handling

While full automation is still rare, partial automation is becoming standard in many industries. This trend will continue as robotics technology improves and costs decrease.

5. Cloud-Based Systems

Cloud computing is making inventory software more accessible and powerful. Cloud-based systems offer several advantages:

- Real-time access to inventory data from anywhere

- Easier collaboration between teams and locations

- Automatic updates and scalability

As more businesses move to the cloud, it will become the standard for inventory management solutions.

6. Sustainability Focus

Environmental concerns are shaping inventory practices. Companies are looking for ways to reduce waste and improve sustainability. This includes:

- Optimizing packaging to reduce material use

- Implementing reverse logistics for product returns

- Using data to minimize overproduction

Sustainable inventory management not only helps the environment but can also reduce costs and improve brand image.

7. Omnichannel Inventory Management

With the rise of e-commerce, businesses must manage inventory across multiple sales channels. Omnichannel inventory management aims to create a seamless experience for customers, whether they shop online or in-store. This approach involves:

- Syncing inventory data across all channels

- Enabling options like buy online, pick up in-store

- Optimizing inventory allocation based on channel demand

As consumer expectations for convenience grow, effective omnichannel strategies will become crucial.

8. Predictive Analytics

Advanced analytics are helping businesses make smarter inventory decisions. Predictive analytics uses historical data and statistical algorithms to forecast future trends. This can help with:

- Anticipating demand fluctuations

- Optimizing stock levels

- Identifying potential supply chain disruptions

As data collection and processing capabilities improve, predictive analytics will become more accurate and valuable.

9. Just-in-Time and Lean Inventory

Many companies are moving towards just-in-time (JIT) and lean inventory practices. These approaches aim to reduce waste by keeping inventory levels as low as possible without risking stockouts. While not new, these strategies are evolving with technology:

- AI-powered demand forecasting makes JIT more feasible

- IoT sensors enable real-time tracking of lean inventory

- Automated systems allow for faster response to demand changes

As supply chains become more agile, JIT and lean practices will likely gain further traction.

10. Mobile Inventory Management

Mobile devices are transforming how inventory is managed on the ground. Smartphones and tablets allow warehouse staff to:

- Update inventory levels in real-time

- Access product information instantly

- Scan barcodes for quick data entry

This mobility improves efficiency and accuracy in day-to-day inventory operations.

Final Words

The future of inventory management is dynamic and technology-driven. From AI-powered forecasting to blockchain-enabled traceability, new tools are reshaping how businesses handle their stock. These innovations promise greater efficiency, accuracy, and responsiveness in inventory management.

However, technology alone is not enough. Successful inventory management will still require human insight and strategic thinking. Companies that blend cutting-edge technology with skilled personnel will be best positioned to thrive.

As these trends continue to evolve, businesses must stay informed and adaptable. Those who embrace these innovations in inventory management will gain a competitive edge in an increasingly complex market.

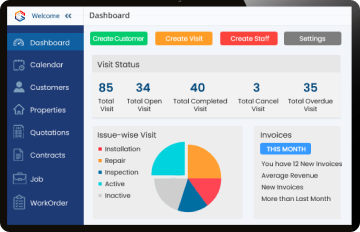

For companies looking to stay ahead of these trends, Genic Solutions offers cutting-edge inventory management tools. Their software incorporates many of the innovations discussed here, helping businesses streamline their operations and boost efficiency. With Genic Solutions, you can transform your inventory management and prepare your business for the future.