In today’s competitive manufacturing and supply chain landscape, businesses continuously seek tools and methodologies to gain a strategic edge. The ability to harness and synchronize multiple operations, especially in vast inventories and complex logistics environments, can be the deciding factor between industry leadership and mere survival.

The ERP management system has long been revered as the fulcrum that consolidates diverse business functions. However, as warehouses burgeon and inventories expand, there emerges a pressing need for more specialized, intricate tools.

Here, the Warehouse Management System (WMS) comes into play, promising precision, efficiency, and real-time insights. As companies strive to achieve the ideal synergy between holistic organizational oversight and granular warehouse operations, understanding the symbiotic relationship between ERP and WMS becomes paramount.

Understanding the Warehouse Management System (WMS)

At its core, a WMS is akin to the central nervous system of a warehouse. It meticulously manages every nuance of inventory flow: from receiving goods to their final dispatch. By offering detailed insights in real-time, a WMS ensures maximum efficiency in inventory movements, placement, and management within the warehouse environment.

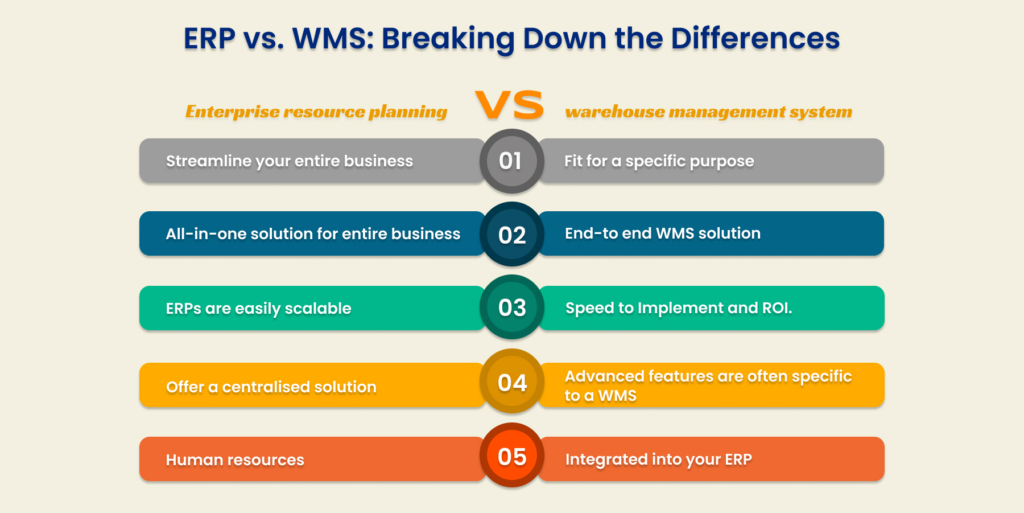

ERP vs. WMS: Breaking Down the Differences

An ERP serves as the organizational brain, integrating various business functions and offering a comprehensive overview. From finance to HR to inventory management, it offers broad-spectrum insights.

On the other hand, a WMS zooms into the intricate details of warehouse operations. It’s like comparing a general practitioner (ERP) with a specialist surgeon (WMS). Both are indispensable, but their focus varies.

Indications That Show Your Business Needs WMS

For some small-scale manufacturers, the inventory capabilities of their ERP might feel adequate. But as complexities mount with business growth, the specialized functionalities of a WMS become more compelling.

A warehouse bustling with myriad inventory items, intricate picking strategies, and multi-location operations will undoubtedly benefit more from the precision of a WMS.

- Escalating Labour Expenses: If operational costs are ballooning without corresponding efficiency gains, WMS can offer a reprieve.

- Increasing Error Trajectory: A spike in wrong shipments, backorders, or customer complaints often signals process inefficiencies ripe for WMS intervention.

- Maxing Out Warehouse Space: Before contemplating a bigger warehouse, consider optimizing the current one with WMS for space efficiency.

Read More – Software Development – Understanding the Process & Choosing a Partner

Integration of WMS with ERP: Crafting a Cohesive Ecosystem

When WMS integrates with ERP, it’s like two puzzle pieces fitting perfectly. While ERP offers an overarching view of the business, WMS provides detailed insights into warehouse-specific operations. The harmonious blend ensures that the entire supply chain, from procurement to sales, functions seamlessly.

However, this integration can be a complex affair, necessitating a meticulous approach. Yet, the efforts pay off the manifold. Many cutting-edge ERP systems now come with in-built WMS functionalities, offering businesses an integrated solution right off the shelf.

The union of ERP and WMS is not just a tech collaboration; it’s a strategic alliance. For businesses looking to optimize, gain insights, and achieve unprecedented operational efficiency, this combo is a game-changer.

As you chart your organization’s growth path, remember that harnessing the combined power of ERP and WMS can unlock unmatched potential in inventory and warehouse management. Embrace this duo for a future marked by growth, agility, and excellence.

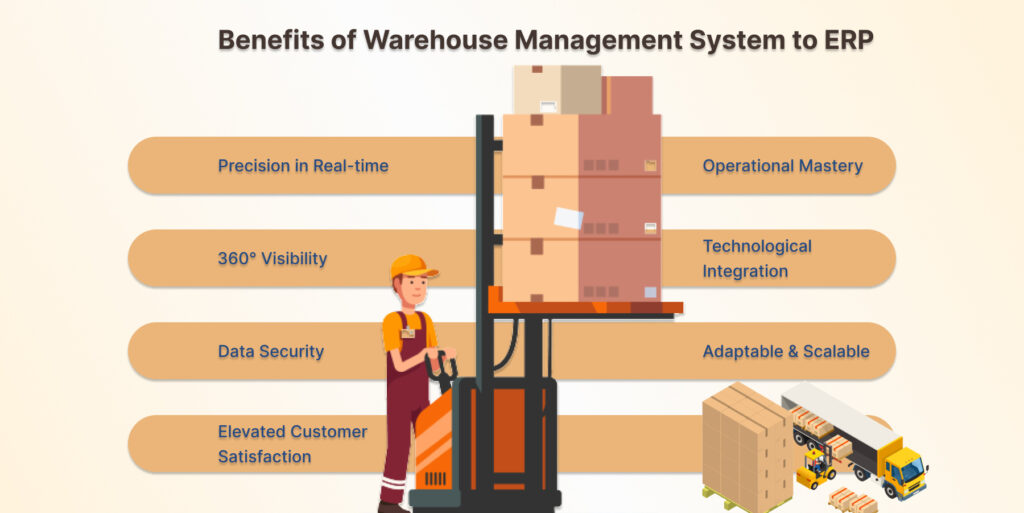

Benefits of Warehouse Management System to ERP

- Precision in Real-time: With WMS, you’re always in the know. Instantly access stock levels, movement histories, and specific locations.

- Operational Mastery: The system aids in perfecting procedures like put-away strategies, cycle counting, stock adjustments, and more. It ensures efficient order processing, reduced errors, and quicker deliveries.

- 360° Visibility: Get unparalleled insights into warehouse activities. From order statuses to performance metrics, everything is at your fingertips.

- Technological Integration: WMS seamlessly integrates with advanced tools such as barcodes and RFID, eliminating manual errors.

- Data Security: Integrated systems ensure data sanctity and authorized access, protecting valuable information.

- Adaptable and Scalable: WMS systems evolve with your business needs, ensuring you’re equipped for both current challenges and future expansions.

- Elevated Customer Satisfaction: With on-point deliveries and reduced mistakes, customer trust and satisfaction soar.

Conclusion

As industries become more competitive, the integration of ERP and WMS offers companies an unparalleled advantage, positioning them as leaders in operational efficiency and customer satisfaction.

Harnessing the power of both ERP and WMS can drastically redefine the supply chain’s operational landscape. When these systems operate in harmony, businesses experience a holistic approach to inventory management, ensuring no aspect is overlooked.

With Genic Solutions at the helm, the synergy becomes even more potent. Our solutions bridge the gap between broad organizational oversight from ERPs and the granular precision of WMS. With advanced functionalities and robust integrations, Genic Solutions ensures that warehouse inventory management software isn’t just managed but optimized, achieving the delicate balance between operational efficiency and resource utilization.