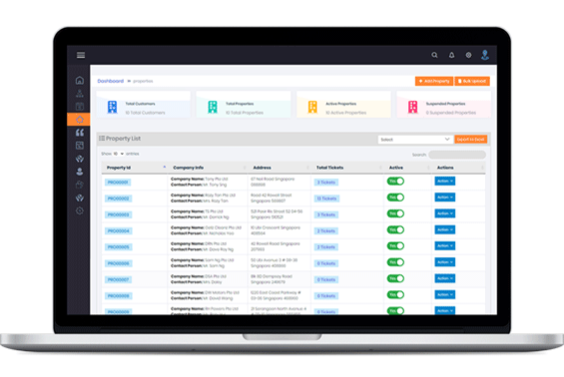

Genic inventory management system can make it easier for you to manage your stock spanning across different locations, all from a single location. With our tech solutions, you can achieve greater efficiency, lower your business costs, and make your customers happy.

Get rid of damaged or defective products from your inventory and maintain all the fluctuations using stock adjustments. You can view stock reports to make informed decisions and decide which products are performing poorly or are no longer in demand. With the help of a single platform, you can decide which products need to be removed or transferred from one location to another.

Maintain your inventory at adequate levels by scanning your product’s barcodes. With the help of barcodes, track the entire life cycle of products in your inventory to when customers place an order to buy them. Accordingly, accurate reports and filtered searches make it easy for you to decide which products can be transferred to another warehouse and which ones you need to restock.

We offer an inventory management system to maintain stock counts, avoid manual processes, reduce errors, and cut the time required to do everything perfectly. So, what are you waiting for? Connect with us!

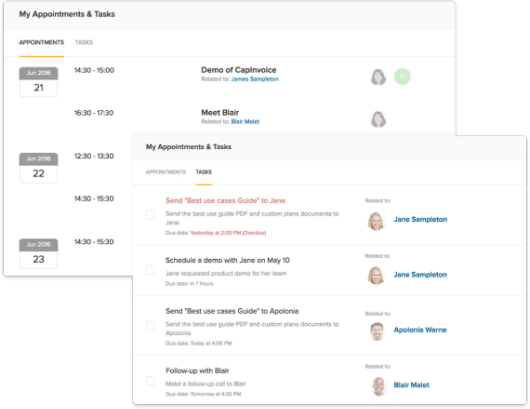

Keep your inventory levels accurate by transferring your stock across different warehouse locations. Different warehouses can have different stock counts. If a warehouse loses a valuable product, you can increase its quantity by transferring more from another location. You can also transfer stock across different locations if some products are performing well in a particular location.

Move your inventory from one location to another without losing any vital information or data. Transferring products across different storage locations can be very tedious and time-consuming if you decide to do it with the help of paperwork. Instead, you can automate this process with the help of Genic inventory management system and do everything without wasting your precious time.